- Hydraulic Valve Direction

- Brand

- Atos (17)

- Badestnost (30)

- Bosch (39)

- Bosch Rexroth (39)

- Brand Hydraulics (20)

- Eaton Vickers (17)

- Enerpac (53)

- Engineers Mate (22)

- Flowfit (62)

- Hawe (32)

- Nachi (31)

- Parker (228)

- Parker Hannifin (17)

- Perfect Hydraulic (148)

- Prince (17)

- Rexroth (203)

- Summit Hydraulics (40)

- Toauto (25)

- Vickers (138)

- Walvoil (31)

- ... (1226)

- Item

- Spool Count

- Suitable Media

- Type

- Valve Operation

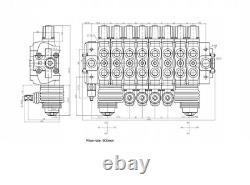

8 Bank Hydraulic Directional Valve for Forest Crane Logging Trailer 90L 2x Joy

NOTE: We issue VAT invoices for countries in the European Union. The distributor is adapted to different machine types, such as B.

Forest machines, tractors, field sprayers, rotors, HDS loaders, construction machines, loaders, excavators, sweepers, industrial machines and other hydraulically controlled devices. Recommended system oil flow: 0 - 90l / min.

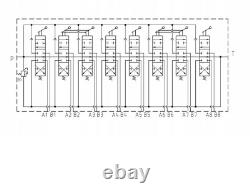

Control example: eight double-acting cylinders. Can be connected in series to an existing system (pressure sleeve required). Recommended system oil flow: 0 - 90 l / min. Both joysticks with five positions (1 - 2 - 0 - 3 - 4) are spring-loaded, i. You return to the vertical yourself. Position 0 neutral (vertical joystick) piston rods of both cylinders are stationary - oil flows to the overflow. Working position 1 (joystick lever in forward position) The piston rod of the first cylinder extends. Working position 2 (joystick lever tilted backwards) The piston rod of the first cylinder retracts. Working position 3 (joystick lever inclined to the left) The piston rod of the second cylinder extends. Working position 4 (joystick lever inclined to the right) The piston rod of the second cylinder retracts. All three position levers (1 - 0 - 2) are spring loaded, i.Position 0 neutral (lever in vertical position) cylinder piston rod is stationary - oil overflows. Working position 1 (lever in forward position) The cylinder piston extends.

The 2 working position (lever backwards) of the piston rod of the cylinder retracts. The lever can be positioned parallel or perpendicular to the joysticks.Pump supply (P): BSP 1 / 2``internal thread return to the tank (T): BSP 3 / 4''internal thread section outlet (A, B): BSP 1 / 2''internal thread. Maximum inlet pressure: 250 bar Maximum return pressure: 50 bar Maximum pressure on the sections: 300 bar. Factory set relief valve to 175Bar Self-adjusting, full rotation, change by 30Bar.

This item is in the category "Business, Office & Industrial\Hydraulics, Pneumatics, Pumps & Plumbing\Valves & Manifolds\Directional Control Valves\Spool Valves". The seller is "hydraulic-center" and is located in this country: PL.

- Suitable Media: Oil

- Connection diameter: 3/4 in 1/2 in

- Manufacturer number: SD8

- Spool Count: 8-Spool

- Valve Operation: Manual

- Maximum Pressure: 4500 psi

- Brand: Perfect Hydraulic

- Maximum Flow Rate: 25 gpm